What Are Airless Pump Bottles And How Do They Work?

Nowadays, airless pump bottles are frequently mentioned in the cosmetic packaging industry. Yet, one may wonder what these airless bottles are exactly. Airless pump bottle represents a revolutionary advancement in packaging technology, offering a sophisticated solution to preserve and dispense various skincare and cosmetic products. The inception of airless pump bottles can be traced back to the mid-20th century, with the initial concept emerging in response to the challenges posed by traditional packaging methods. Airless bottles have become increasingly popular in the field of packaging, particularly in the cosmetic and skincare industries. As cosmetic formulations became more advanced and sensitive to environmental factors, the need for a packaging system that could protect the integrity of the product from air exposure, contamination, and oxidation became increasingly evident.

Airless pump bottles operate on a vacuum-based dispensing mechanism, ensuring the product is protected from external elements throughout its usage. Unlike conventional pump bottles, airless systems eliminate the need for a tube, instead utilizing a vacuum to push the product upward. One of the key benefits of airless bottles is their ability to prevent air exposure and its detrimental effects on the product. Unlike traditional pump bottles, which allow air to enter the container over time, airless pump bottles effectively minimize the risk of oxidation. With their sleek design and functional advantages, airless pump bottle has become an indispensable choice for brands aiming to deliver premium and long-lasting formulations to consumers in the contemporary beauty and skincare market.

How Do Airless Pump Bottles Work

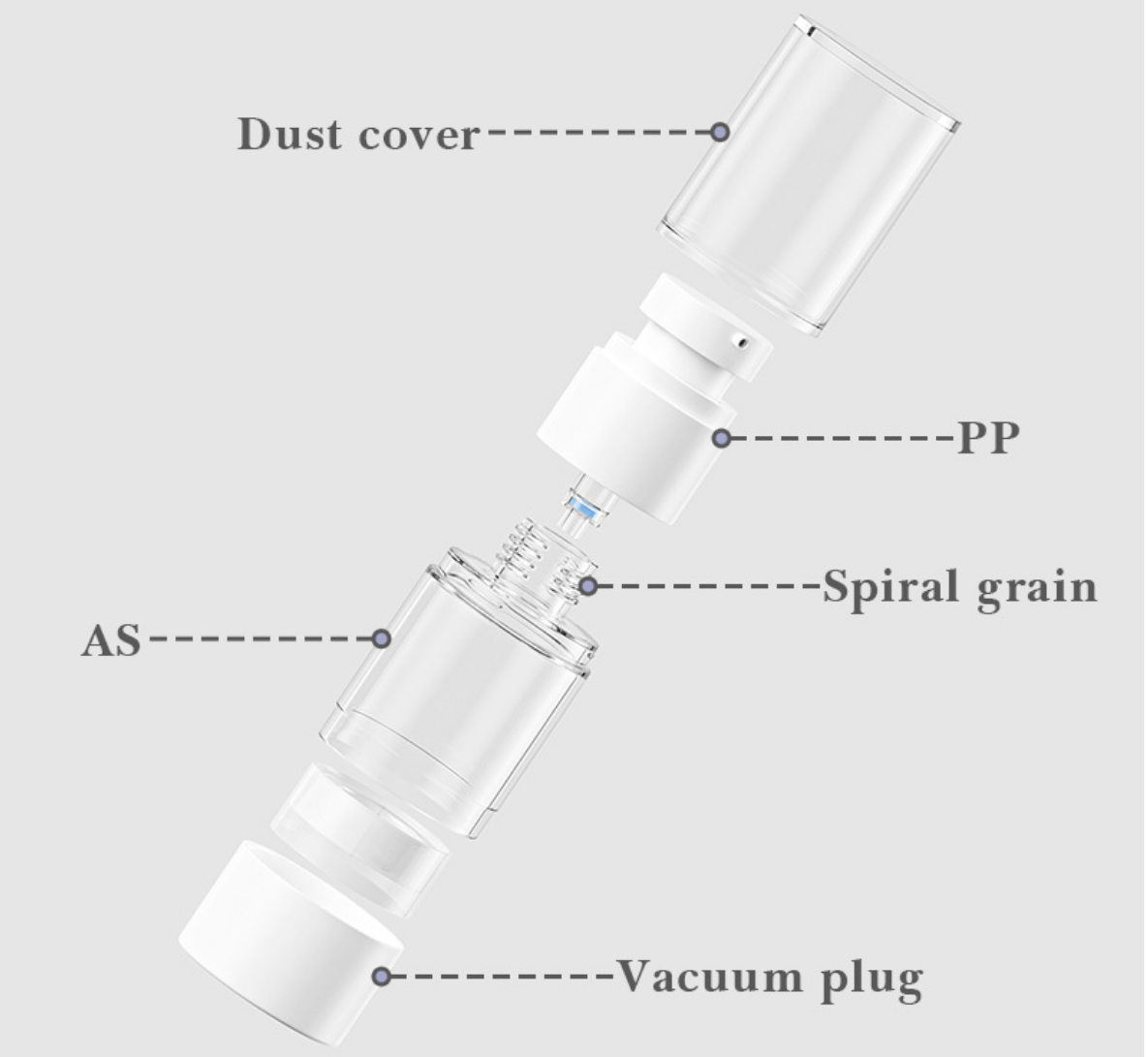

Airless pump bottles operate through a sophisticated vacuum-driven mechanism, offering a solution to preserve and dispense cosmetic and skincare formulations with enhanced precision and longevity. The key innovation lies in the absence of a traditional tube commonly found in conventional pump bottles. A typical airless pump bottle consists of three main parts: the airless bottle, the pump, and the actuator. Typically, the flask is composed of sturdy material, for instance, either glass or top-notch plastic, working to shield its contents from external variables such as sunlight or heat. Airless pump bottles also have a piston at the base of the container, coupled with a pump mechanism. When the pump is activated, a vacuum is created within the container, compelling the diaphragm or piston to move upward and displace the product. The actuator dispenses the desired quantity of product when pressed, and it can be found at the pump's uppermost part.

Notably, the remaining product is not exposed to air as the piston rises, which prevents oxidation and contamination. This airtight mechanism ensures that the product remains fresh and compelling until the last drop is utilized. Additionally, the absence of an air tube within the airless bottle reduces product waste and allows for easy dispensing, making airless pump bottles an eco-friendly and user-friendly packaging option.

How To Open An Airless Pump Bottle

Some people might wonder how to open an airless pump bottle. First, ensure the airless bottle is upright. Press down on the pump top a few times to initiate the vacuum-sealed mechanism. Once the pump dispenses the product, it's ready for regular use.

With so many components, there is a possibility for an airless bottle not to work correctly. Well how do you open an airless pump bottle not working properly? To get the product to dispense, cap it, turn it upside down and tap it against a hard surface 10 to 15 times, then try to pump it again. After trying that, it should begin to work properly.

What Differentiates Airless Pump Bottles From Regular Bottles

Airless pump bottles set themselves apart from regular bottles by eliminating the need for a conventional tube. Airless bottles prove to be a significant upgrade from regular bottles as they offer distinct features that provide several advantages in product preservation and dispensing. Unlike regular bottles that depend on gravity for product flow, airless bottles utilize an ingenious vacuum-based system to expel the product. This uniqueness ensures that there is no contact with air, preventing oxidation and contamination, which ultimately enhances the shelf life of the content.

Apart from their preservation benefits, airless pump bottles also offer convenience in product usage. With traditional bottles, consumers often need help retrieving the entire content, particularly when nearing the end. Airless bottles effectively solve this problem, as the piston system ensures that every last drop of the product is efficiently dispensed. Furthermore, airless pump bottles have a mechanism that prevents backflow, allowing users to dispense just the right amount without spills or drips. This feature not only enhances precision and control but also minimizes waste and maintains the overall hygiene of the product.

Additionally, airless bottles' sleek and modern design contributes to their differentiation. The absence of a visible tube and the vacuum-driven mechanism gives airless pump bottles a more sophisticated and aesthetic appeal. This not only aligns with the premium nature of many beauty and skincare products but also enhances the overall branding and presentation, making airless bottles a preferred choice for brands aiming to convey a sense of innovation and quality in their packaging.

The Advantages Of Airless Pump Bottles

Airless pump bottle offer innumerable benefits that make them a desirable option for customers and businesses. Airless pump bottles outperform other containers for cosmetics in terms of design, appearance, functionality, and ease of use.

Due to their distinct advantages, airless pump bottles have become increasingly popular among customers. From a customer perspective, these innovative containers offer a more efficient and controlled dispensing experience. These airless bottles are portable and easy to use, and the risk of spillage is negligible. The vacuum-based mechanism ensures precise product delivery, reducing the risk of over-dispensing and minimizing waste. Airless pump bottles provide better product protection and preservation. This feature is especially appreciated when travelling or using products on the go. The lack of air exposure ensures the contents remain fresh and contamination-free, increasing the product's shelf life. This feature is particularly beneficial for expensive skincare or cosmetic products.

From a business standpoint, airless pump bottles offer several advantages that can contribute to increased sales and customer satisfaction. Firstly, these containers visually look stunning and provide a sense of luxury to the products they hold. Although the bottle's usability remains unaffected by its looks, its appealing appearance undoubtedly adds uniqueness to your product. The sleek design and smooth functionality of airless bottles create a premium image that can attract discerning customers. Additionally, airless pump bottles are an excellent choice for products containing active ingredients or specific storage requirements. The airtight seal ensures that the product remains potent and effective throughout its lifespan, thus reducing the likelihood of unsold inventory and potential product returns.

Furthermore, airless pump bottles contribute to environmental sustainability as well. Thanks to the precise dispensing mechanism, the reduced product waste aligns with eco-friendly practices. Additionally, the airtight seal helps preserve the integrity of formulations, minimizing the need for preservatives that can have environmental implications. Also, many airless bottles are made of high-quality polypropylene, a recyclable plastic. By promoting longer product lifespans and reducing the environmental impact of packaging waste, airless pump bottles align with the trend towards more sustainable and responsible business practices.

Reasons To Switch To Airless Bottles

There are several compelling reasons to consider switching to airless pump bottles, especially those that are BPA-free and rust-resistant. Firstly, the absence of Bisphenol A, more commonly known as BPA, in these airless bottles ensures a safer packaging solution. BPA is a chemical compound commonly found in various everyday products, including plastic bottles, and it has been associated with potential health risks. By opting for BPA-free airless bottles, businesses can prioritize consumer safety and well-being, addressing concerns about exposure to harmful chemicals in everyday products.

Moreover, the rust-resistant feature in airless pump bottles enhances the durability and longevity of the packaging. This is especially crucial for products with formulations that may interact with metal components in traditional packaging, leading to contamination and compromised product quality. Rust can contaminate the product with harmful particles, rendering it unsuitable for use. On the other hand, airless bottles are specifically designed to prevent the entry of air, which can cause oxidation or rust. This feature ensures that the product remains intact and of high quality for a more extended period, making airless bottles an ideal choice for preserving the efficacy and freshness of various cosmetic and skincare products.

In summary, the switch to BPA-free and rust-resistant airless pump bottles aligns with health and safety considerations and contributes to the overall quality and longevity of the packaged products, meeting the demands of both businesses and discerning consumers in the beauty and skincare industry.

Custom Made Airless Pump Bottles

Custom-made airless pump bottles are a game-changer in the cosmetic industry. Custom airless bottles represent a solution for brands seeking a unique and personalized packaging experience. In the competitive landscape of the beauty and skincare industry, where aesthetics play a pivotal role, custom airless bottles allow businesses to align their packaging with brand identity. The customization options are diverse, from selecting specific materials to incorporating unique shapes, colors, and branding elements. This level of personalization not only enhances brand recognition but also creates a distinct and memorable presence on the shelves, helping products stand out in a crowded market. The benefits of custom-made airless pump bottles are unmatched, offering improved product preservation and a sleek and luxurious packaging solution that appeals to consumers seeking innovation and sophistication.

Furthermore, custom airless bottles offer practical advantages tailored to the product's specific needs. Brands can choose the ideal size, pump mechanism, and features that complement the characteristics of their formulations. Whether it's a luxury skincare serum requiring precise dispensing or a body lotion needing a larger capacity, customization perfectly matches the product and its packaging. This tailored approach ensures that the functionality of the airless pump bottle aligns seamlessly with the requirements of the product it houses, providing both businesses and consumers with an optimal and uniquely branded packaging solution.

In conclusion, the evolution of airless pump bottles signifies a transformative leap in packaging technology. From their mid-20th-century inception as a response to traditional packaging challenges, airless bottles have become a hallmark in the cosmetic and skincare industries. Their vacuum-driven mechanism, eliminating the need for tubes, ensures optimal product preservation and dispensing precision. The advantages for both consumers and businesses are compelling, ranging from extended shelf life and reduced waste to enhanced product efficacy. Custom-made airless bottles add a personalized touch, aligning with brand identity and standing out in the competitive market. Furthermore, switching to BPA-free and rust-resistant variants of airless pump bottles signifies the commitment to safety and quality. As the beauty and skincare industry embraces sustainability, airless pump bottles emerge as eco-friendly packaging champions. The combination of innovation, customization, and environmental responsibility makes airless pump bottle an indispensable choice for brands striving to deliver excellence in the dynamic world of packaging.